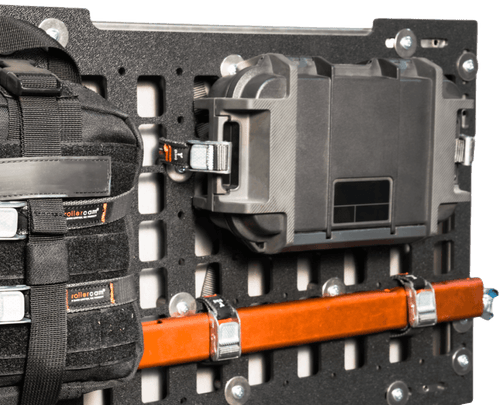

At Rollercam®, our goal is to engineer gear that redefines reliability. Every product is designed with purpose—to simplify the toughest tasks and to endure the elements without fail.

We believe that when your gear is built to perform, it gives you the freedom to focus on what matters most: the journey ahead. Rooted in the rugged spirit of Utah, our designs are as strong as the landscapes that inspire them, crafted to support those who push boundaries, from job sites to the wild outdoors.

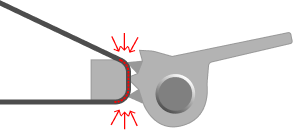

When securing a cam strap, the maximum force applied by pulling is often limited in a standard cam by friction between the cam body and webbing at a fixed point, which reduces its ability to hold firmly.

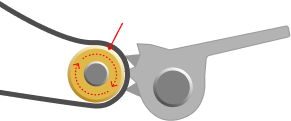

The Rollercam® design minimizes this friction, making it easier to apply higher force with less effort. By dissipating frictional force through our signature brass roller, Rollercam® buckles have a significant increase in maximum holding force, providing a secure hold without extra strain.

friction solution

Decreased friction due to roller design.

Engineered to reduce friction,

delivering stronger hold and

smoother use.

- Friction dissipated through roller.

- Our design eliminated the extra friction for higher holding force and ease of use.

Standard Cam

friction problem

High friction concentrated at cam

Friction in standard cams restricts tightening ability, resulting in

reduced holding force.

- Friction concentrated to a fixed point.

- The more force applied to the strap, the less holding force you achieve.

Frequently Asked Questions

From the design of our cam buckles to understanding load capacities, we’re here to provide details on what makes Rollercam® the best.

-

What makes Rollercam® the best cam straps?

Our signature roller design eliminates friction between the cam and webbing, allowing for higher tension with less effort. This innovation gives you a secure hold without the hassle of over-tightening or loosening straps on the road.

-

What materials are used in Rollercam® cam buckles?

Our cam buckle body and thumb release are made from corrosion-resistant Zamak 2 alloy, known for its strength and durability. The roller is crafted from marine-grade brass, and the springs, roller shaft, and thumb release shaft are stainless steel, ensuring performance and longevity.

-

What is the difference between Working Load and Max Load?

The Working Load is the maximum weight an individual Rollercam® strap can securely hold with 0% displacement under normal conditions. This is calculated using a safety factor of 3, meaning our Max Load is approximately three times the Working Load. While Max Load indicates the theoretical maximum capacity, Working Load represents the safe, recommended limit for regular use, ensuring reliability and minimizing risk. Need more load? Add more straps.

-

How well does Rollercam® handle saltwater and harsh environments?

With stainless steel, marine brass, and Zamak 2 alloy components, Rollercam® straps are built for salt exposure and rough conditions. Based in Salt Lake City, we test for durability in environments with high salt content. Occasional silicone spray can help keep things running smoothly.

-

What type of webbing is used in Rollercam® straps?

Unless otherwise specified, our straps use a UV-resistant, high-tenacity polypropylene blend. This webbing resists water absorption and maintains a firm grip even when wet, ensuring reliability in challenging conditions.