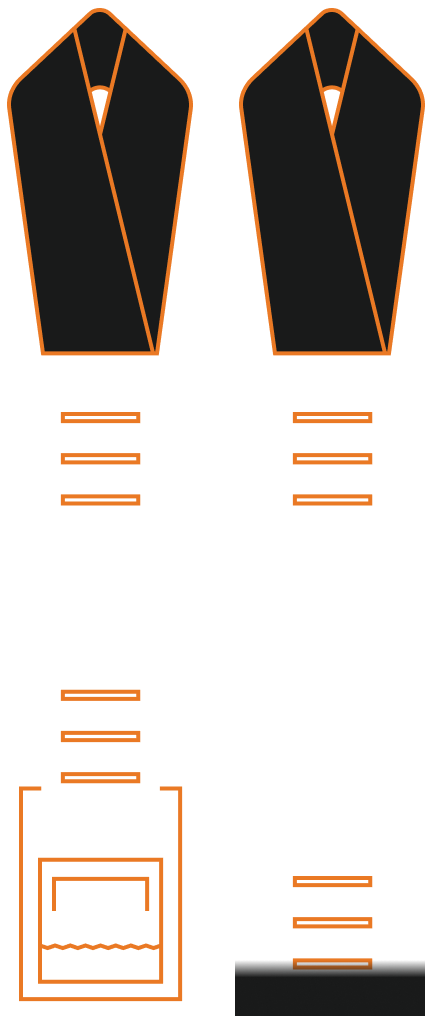

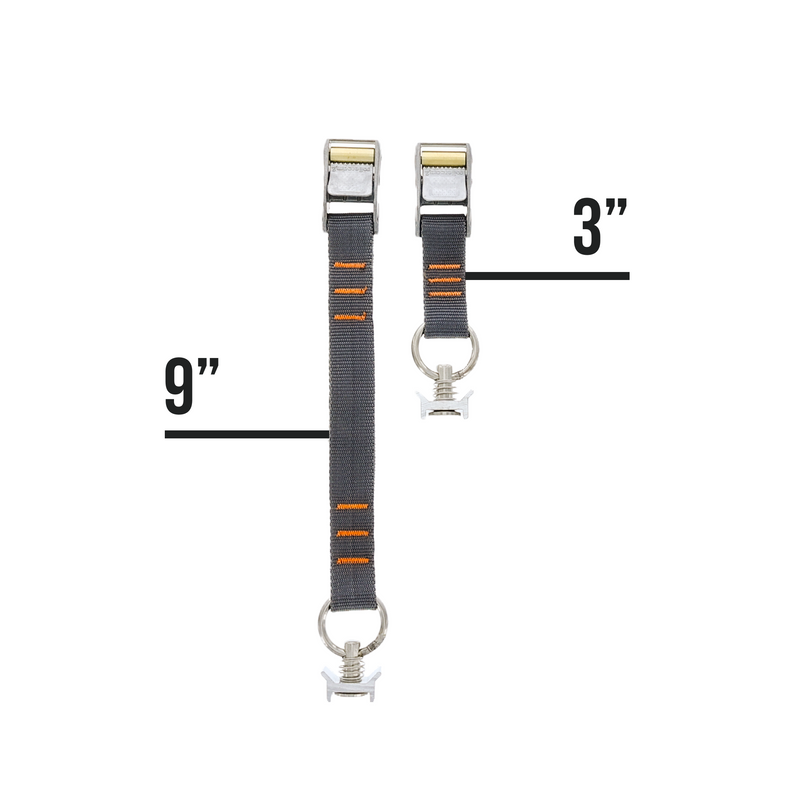

LOOP END

LENGTH RANGES FROM 1’ TO 20’

SIGNATURE ROLLERCAM® BUCKLE

STRAIGHT END TO LOOP THROUGH BUCKLE

$30.00

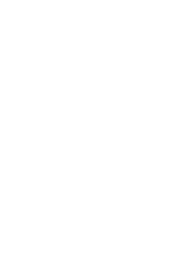

Material: Polypropylene Webbing

Signature Rollercam® Buckle

T-135 Polyester Thread

High Tenacity Webbing

Triple-Bar Tack Stitching

Working Load 350 lbs

Woven-in Length

Includes: Two (2) Straps in Selected Variations

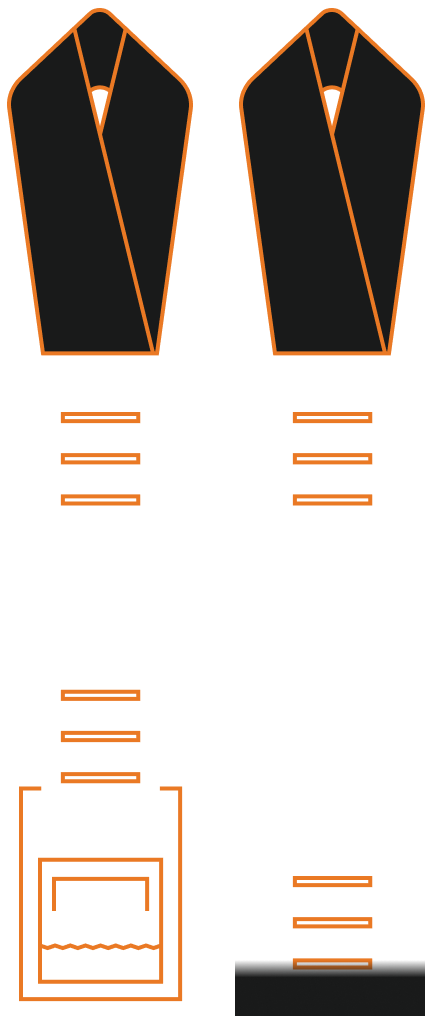

Built for L Track systems in truck beds, trailers, vans, and more, the Rollercam® L Track Kit delivers customizable, rock-solid load security for every haul. Whether you’re locking down heavy equipment for off-road adventures or keeping cargo in place during daily transport, this kit is engineered for uncompromising strength and flexibility.

Each strap is equipped with our patented Rollercam® buckle, eliminating friction for effortless tightening and superior holding power—because when your gear matters, standard straps just won’t cut it.

Heads up: Low-profile L-Tracks in most van installations will not fit our fittings.

Set Options

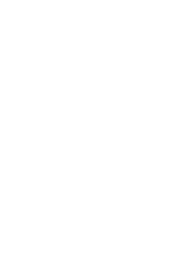

LOOP END

LENGTH RANGES FROM 1’ TO 20’

SIGNATURE ROLLERCAM® BUCKLE

STRAIGHT END TO LOOP THROUGH BUCKLE

Woven-in Length on Select Models

High Tenacity Polypropylene Webbing

Stainless Steel Shaft and Springs

Marine Grade Brass Roller

350lb Working Load Limit on 1” Strap

Three Strap Sizes for Ultimate Versatility