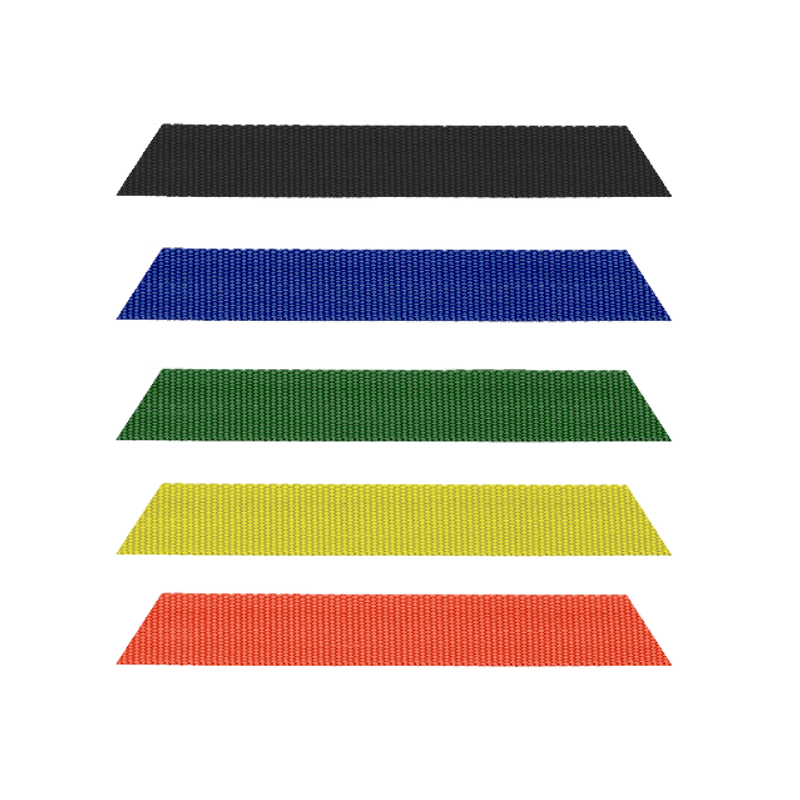

Design Your Own Strap (Polyester Webbing Only)

$9.50

Material: Polyester Webbing

Signature Rollercam® Buckle

T-135 Polyester Thread

High Tenacity Webbing

Triple-Bar Tack Stitching

Working Load 350 lbs

Woven-in Length

Off-the-shelf straps? Not your style. With Build Your Own Polyester Webbing, you call the shots. Select your ideal length and end type to create a custom tie-down system built for your exact needs—whether you’re locking down gear for a rugged overland trip or securing heavy-duty loads with confidence.

Chose Your End Type:

- Straight End: For secure, no-fuss connections.

- Loop End: Ideal for anchor points and rooftop setups.

- Hook End: Quick, versatile, and reliable attachments.

- Carabiner End: Heavy-duty locking for maximum security.

Don’t see the exact setup you need? Hit us up—we’ll sew you something special.

CUSTOMERS ALSO BOUGHT

CUSTOMER REVIEWS

don’t just take our word for it

Everything you need to know

-

What makes Rollercam® the best cam straps?

-

What materials are used in Rollercam® Cam Buckles?

-

What is the difference between Working Load and Max Load?

-

How well does Rollercam® handle saltwater and harsh environments?

-

What type of webbing is used in Rollercam® straps?

-

What’s the difference between the Classic and Expedition models?

GEAR UP

related products

Product Reviews